What is K-Factor in Sheet Metal Design?

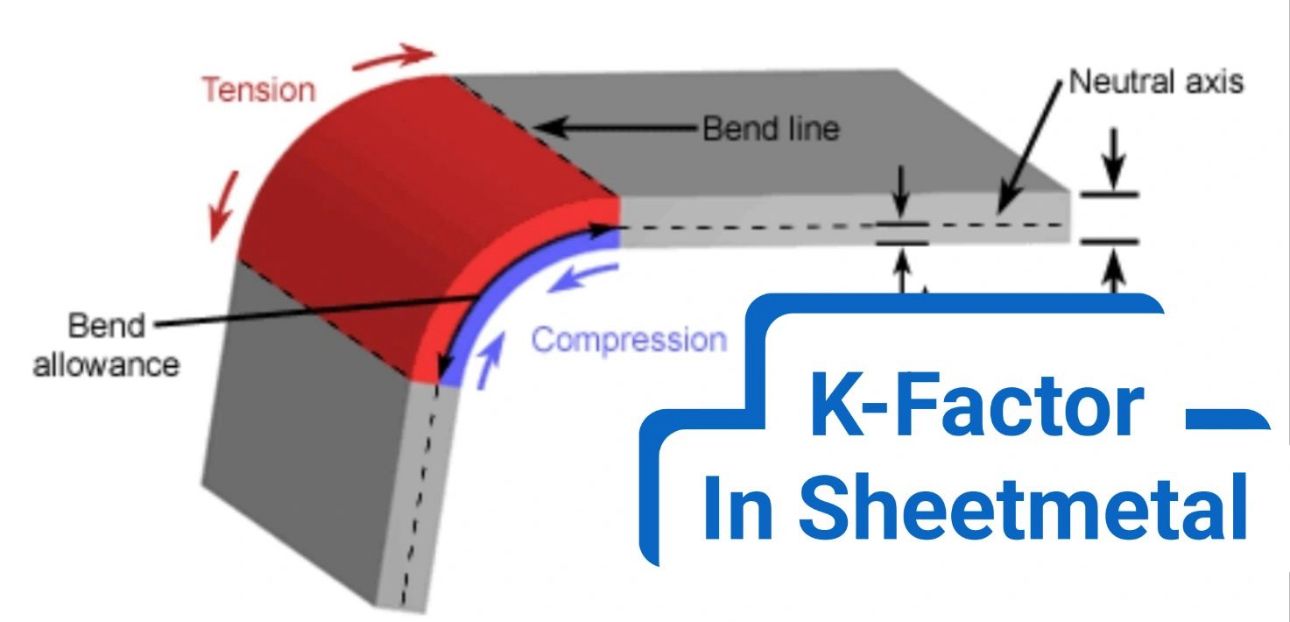

K-factor (bending factor) is used to calculate the bend allowance and locate the neutral axis of a sheet metal part during bending operations.

1️⃣ Definition of K-Factor

The K-factor is the ratio of the neutral axis position to the material thickness (t) in a bending operation. Its value ranges between 0 and 1.

2️⃣ Formula of K-Factor

K=Neutral AxistK = \frac{\text{Neutral Axis}}{t}K=tNeutral Axis

Using bend radius (R):K=R+(t/2)tK = \frac{R + (t/2)}{t}K=tR+(t/2)

where:

- K = K-factor

- R = Bend radius

- t = Material thickness

3️⃣ Interpretation of K-Factor

- K = 0: Neutral axis at the inside bend surface (minimum bend allowance)

- K = 0.5: Neutral axis at midpoint of thickness (common/average)

- K = 1: Neutral axis at outside bend surface (maximum bend allowance)

4️⃣ Typical K-Factor Values

- Air bending: 0.33 – 0.5

- Bottoming: 0.5 – 0.67

- Coining: 0.67 – 1.0

5️⃣ Factors Influencing K-Factor

- Material properties (strength, hardness, ductility)

- Bend radius (R) relative to thickness (t)

- Material thickness (t)

- Bending process (air bending, bottoming, coining)

- Tooling design and punch/die geometry

Why K-Factor Matters

Selecting the correct K-factor ensures accurate bend allowance calculations, which leads to correct flat pattern dimensions and consistent production of complex sheet metal parts.

Formula reminder — Bend allowance uses K-factor:

Total bend allowance and flat length calculations require the chosen K to position the neutral axis when converting between bent and flat dimensions.

🌟 Join Our Premium Job Group Today!

Get access to 100+ daily job & internship updates from top OEMs & MNCs.

Includes HR emails, contact numbers, job details, Google forms & placement drive updates across various roles & departments.

Stay ahead with exclusive opportunities shared only in the premium group.

👉 Join Now: Click Here

Don’t miss out—your next career move starts here!