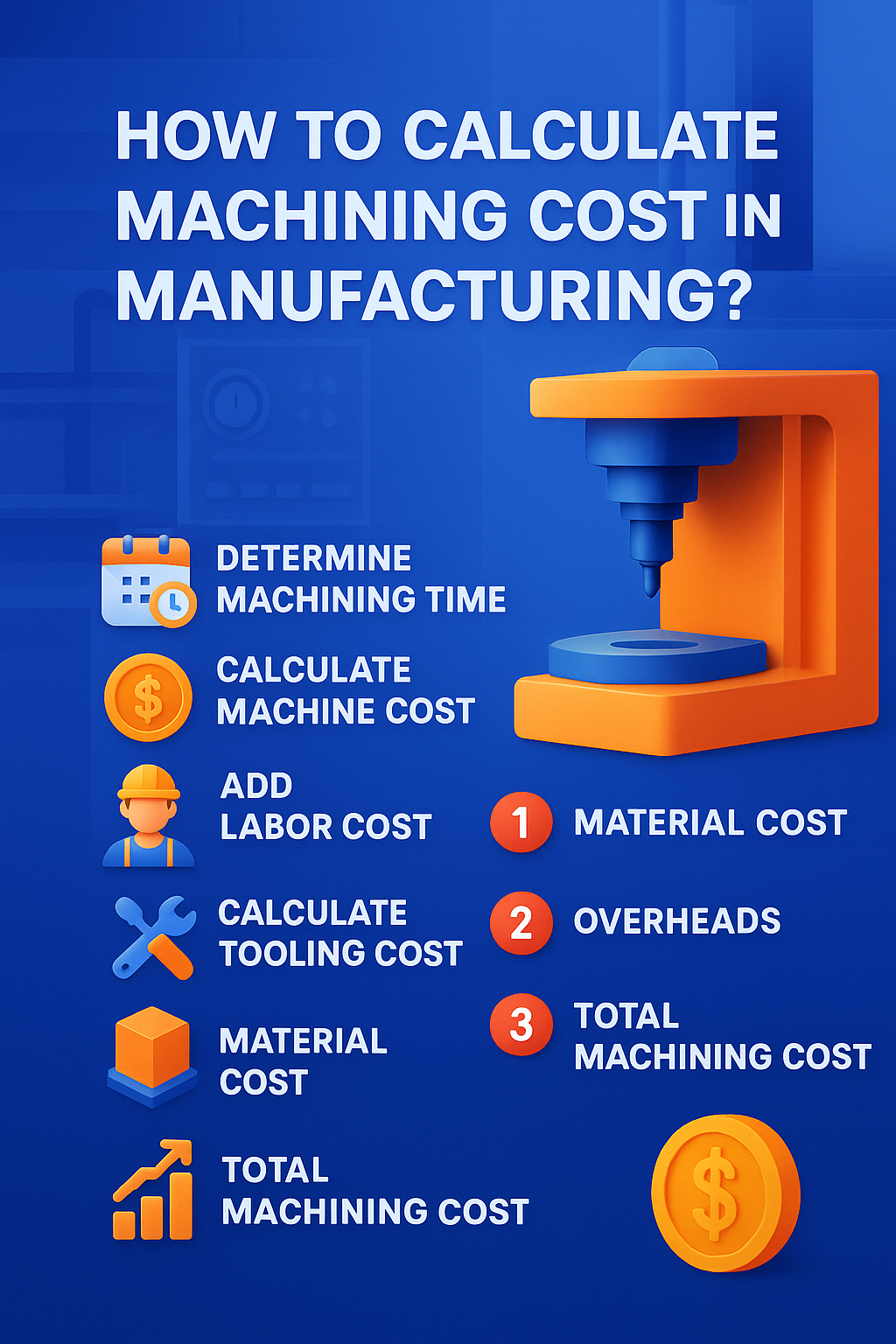

🛠️ How to Calculate Machining Cost in Manufacturing?

Machining processes — such as turning, milling, drilling, and grinding — are the backbone of modern manufacturing. Industries like automotive, aerospace, and heavy machinery rely heavily on precision machining.

For manufacturers, accurately calculating machining cost per part is critical to:

✅ Stay competitive

✅ Ensure profitability

✅ Optimize cost control

✅ Quote correct pricing to customers

In this article, we’ll explain the step-by-step process to calculate machining cost in manufacturing.

📌 Step 1: Determine Machining Time

Machining time depends on:

- Cutting speed (m/min)

- Feed rate (mm/rev or mm/min)

- Length of cut (mm)

Formula: Machining Time (min)=Length of CutFeed × Spindle Speed\text{Machining Time (min)} = \frac{\text{Length of Cut}}{\text{Feed × Spindle Speed}}Machining Time (min)=Feed × Spindle SpeedLength of Cut

📌 Step 2: Calculate Machine Cost

Machine cost is calculated by multiplying the machine hourly rate with the machining time.

Formula: Machine Cost=Machining Time (hr)×Machine Hourly Rate\text{Machine Cost} = \text{Machining Time (hr)} × \text{Machine Hourly Rate}Machine Cost=Machining Time (hr)×Machine Hourly Rate

📌 Step 3: Add Labor Cost

Include operator wages for setup time + machining time. Labor Cost=Operator Rate per Hour×Time\text{Labor Cost} = \text{Operator Rate per Hour} × \text{Time}Labor Cost=Operator Rate per Hour×Time

📌 Step 4: Tooling Cost

Every tool has a limited life. Spread its cost over the number of parts it can produce. Tooling Cost per Part=Tool PriceNumber of Parts Produced\text{Tooling Cost per Part} = \frac{\text{Tool Price}}{\text{Number of Parts Produced}}Tooling Cost per Part=Number of Parts ProducedTool Price

📌 Step 5: Material Cost

Calculate raw material cost: Material Cost=Weight of Material×Material Rate per kg\text{Material Cost} = \text{Weight of Material} × \text{Material Rate per kg}Material Cost=Weight of Material×Material Rate per kg

📌 Step 6: Overheads

Overheads include indirect costs like power, maintenance, rent, and admin expenses. These are usually added as a percentage of direct cost (e.g., 15–25%).

📌 Step 7: Total Machining Cost

Finally, sum all costs: Total Machining Cost per Part=Material+Machine+Labor+Tooling+Overheads\text{Total Machining Cost per Part} = \text{Material} + \text{Machine} + \text{Labor} + \text{Tooling} + \text{Overheads}Total Machining Cost per Part=Material+Machine+Labor+Tooling+Overheads

✅ Example: Machining Cost Calculation

- Material Cost = ₹120

- Machine Cost = ₹80

- Labor Cost = ₹50

- Tooling Cost = ₹20

- Overheads = ₹30

Total Cost per Part = ₹300

📊 Key Benefits of Accurate Machining Costing

- Competitive pricing in tenders & quotations

- Improved profitability

- Better decision-making for make vs buy

- Optimized production planning

🌟 Join Our Premium Job Group Today!

Get access to 100+ daily job & internship updates from top OEMs & MNCs.

Includes HR emails, contact numbers, job details, Google forms & placement drive updates across various roles & departments.

Stay ahead with exclusive opportunities shared only in the premium group.

👉 Join Now: Click Here

Don’t miss out—your next career move starts here!