Hi everyone!

Today I want to talk about something really important in manufacturing and quality work — the shift from inspection to prevention.

For a long time, we’ve seen quality as something that happens at the end of the line — you build the product, then check it, and fix anything that’s wrong.

But this approach is reactive. It means we’re always fixing mistakes after they happen.

Let’s talk about how we can move beyond that.

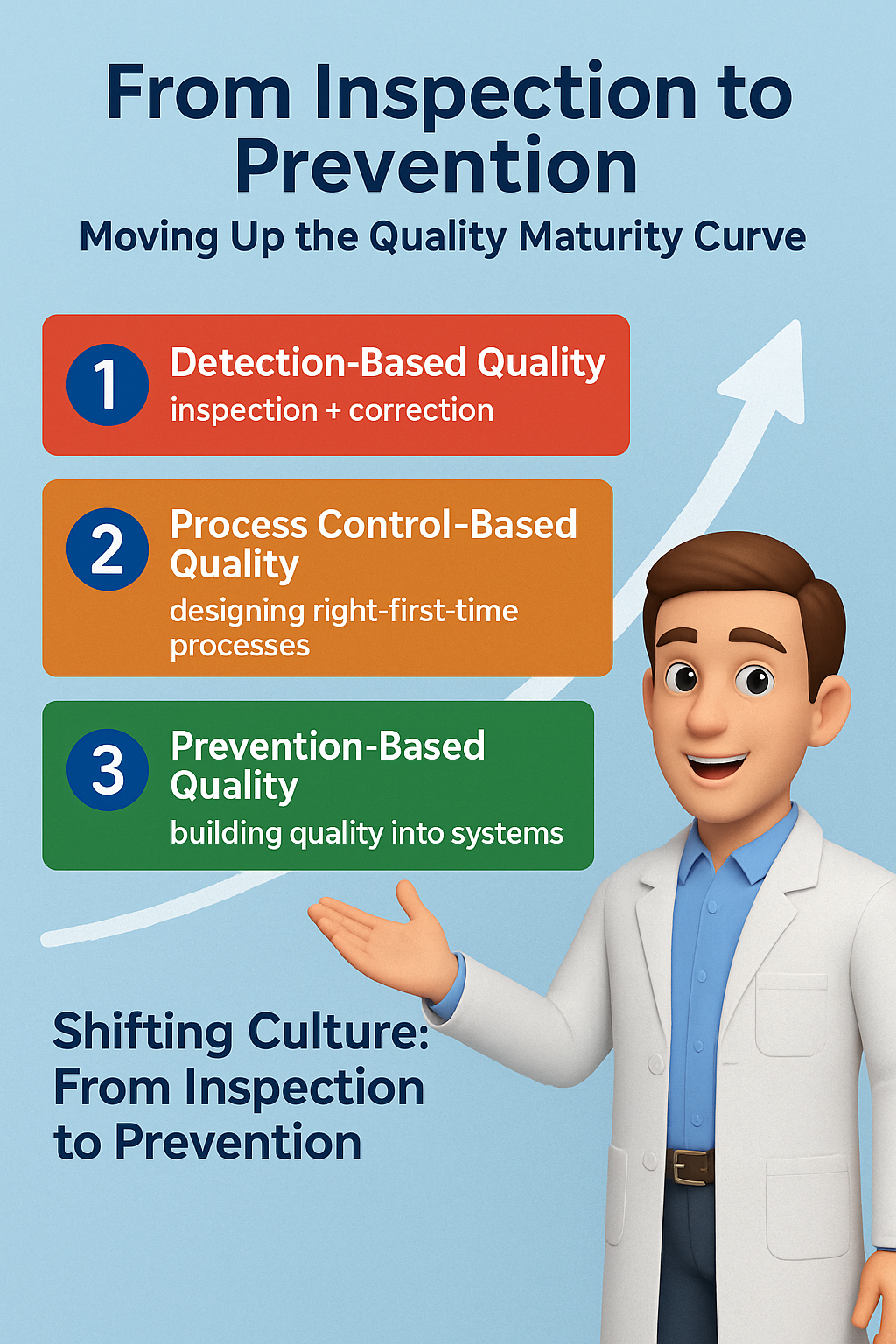

Organizations usually go through three stages of quality:

Stage 1: Detection-based quality

This means inspecting and correcting. It’s basic, and common, but not efficient.

Stage 2: Process-control based quality

Here, we focus on creating stable processes that deliver good results the first time. It’s more reliable.

Stage 3: Prevention-based quality

This is the best stage. Quality is built into the design, the systems, the training, and even the leadership behavior.

You don’t just catch mistakes — you prevent them

So how do we shift to this prevention mindset?

Here are a few key things:

- Start quality planning early, during design.

- Use tools like FMEA and APQP to find risks before they cause problems.

- Focus on supplier quality from the beginning, not just during inspection.

- Make sure everyone in the company feels responsible for quality — not just the QA team.

- And finally, learn from past mistakes using data and feedback.

So the big idea is this:

Don’t wait to find problems. Build systems that stop them from happening at all.

That’s how you move from inspection… to prevention.

Thanks for watching!

If this helped, feel free to like or share it. See you in the next one!